-

Environmental- friendly paint room

Environmental- friendly paint room -

High frequency welding machine

High frequency welding machine -

Laser cutting

Laser cutting -

Plate flatting

Plate flatting -

CNC punch press

CNC punch press -

Belt making unit

Belt making unit

Weichuang's Production Scale

Weichuang, as an established R&D and manufacturing enterprise for generator set radiators, operates two standardized production bases spanning over 60,000 square meters. With a technical team of 50+ core engineers, we have built a comprehensive industrial system covering R&D, production, and testing, achieving an annual production capacity of 150,000 units/sets.

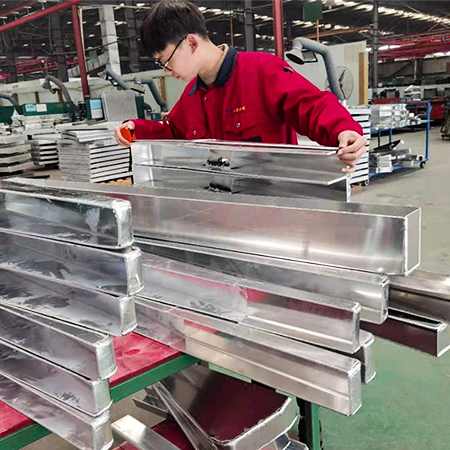

Professional advanced sheet metal radiator manufacturing equipment to ensure the quality of the products, high efficiency and delivery guarantee.

-

01Blanking

01Blanking -

02Laser cutting

02Laser cutting -

03Core installation

03Core installation -

04Connection Pipes Manufacturing

04Connection Pipes Manufacturing -

05Powder Coating

05Powder Coating -

06Welding

06Welding -

07Leakage Check

07Leakage Check

Laboratory/Inspection

Weichuang operates its own performance laboratory equipped with advanced testing facilities capable of evaluating radiators' key performance

metrics including thermal dissipation, vibration resistance, corrosion resistance, and high/low temperature endurance.

Notably, Weichuang currently maintains China's only laboratory capable of conducting actual performance tests on 1,200kW host unit radiators.

-

Heat dissipation

-

Shock resistance

-

Corrosion resistance

-

High and low temperatures

Detection Test

Implement the principle of inspection for each process

Punching quality inspection, core quality inspection, assembly quality inspection, make every quality inspection traceable.

English

English  русский

русский  Français

Français  bahasa Indonesia

bahasa Indonesia  عربى

عربى  中文简体

中文简体